Manufacturing Execution System

What's a MES software?

MES (Manufacturing Execution System) software or production monitoring software is an IT tool, integrated into the company's information system, whose primary objective is to collect all production data in real time in order to optimize the monitoring and management of industrial processes. It is a real decision-making tool and is fully part of a continuous improvement process.

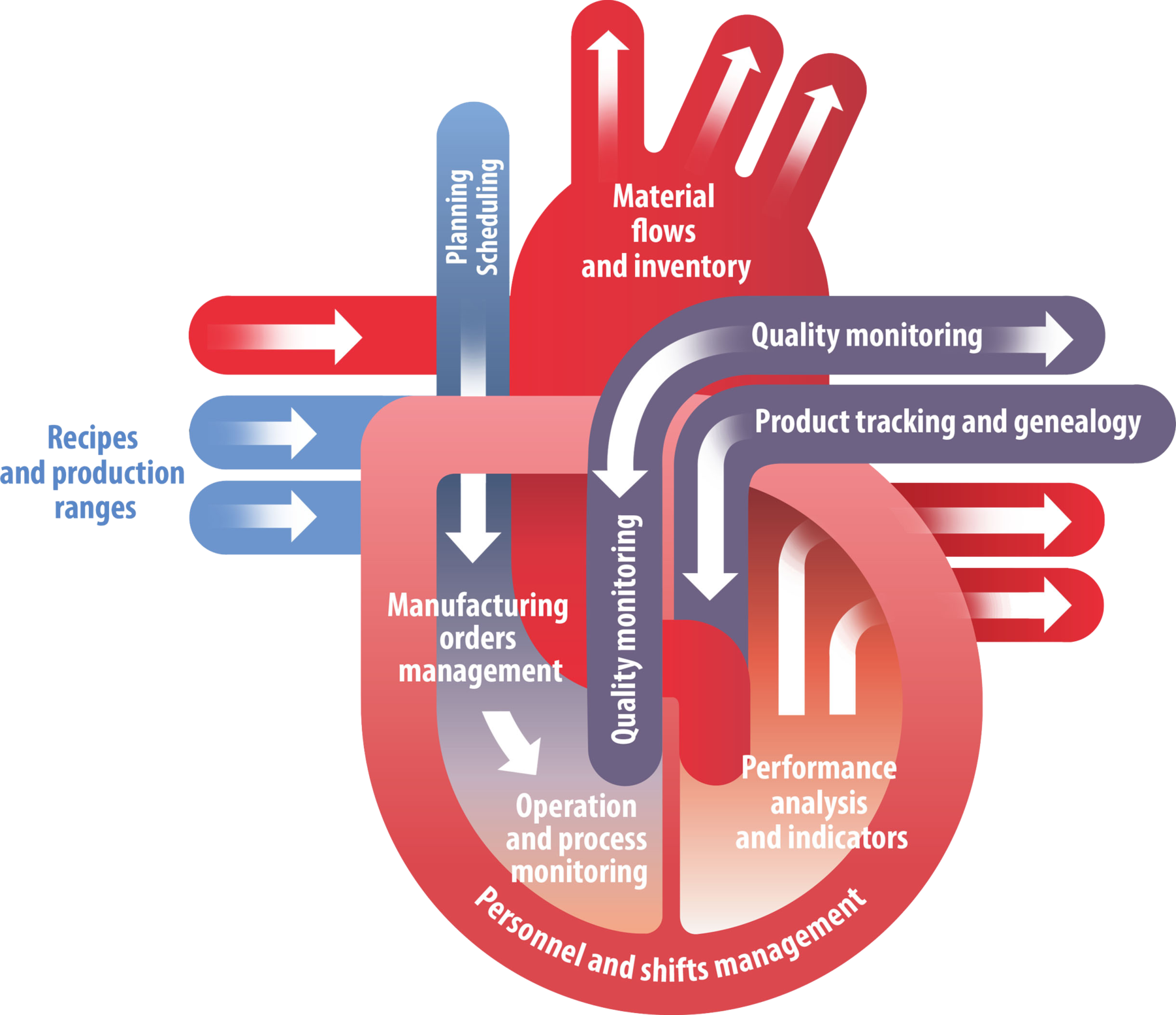

COOX : the Heart of Industry 4.0

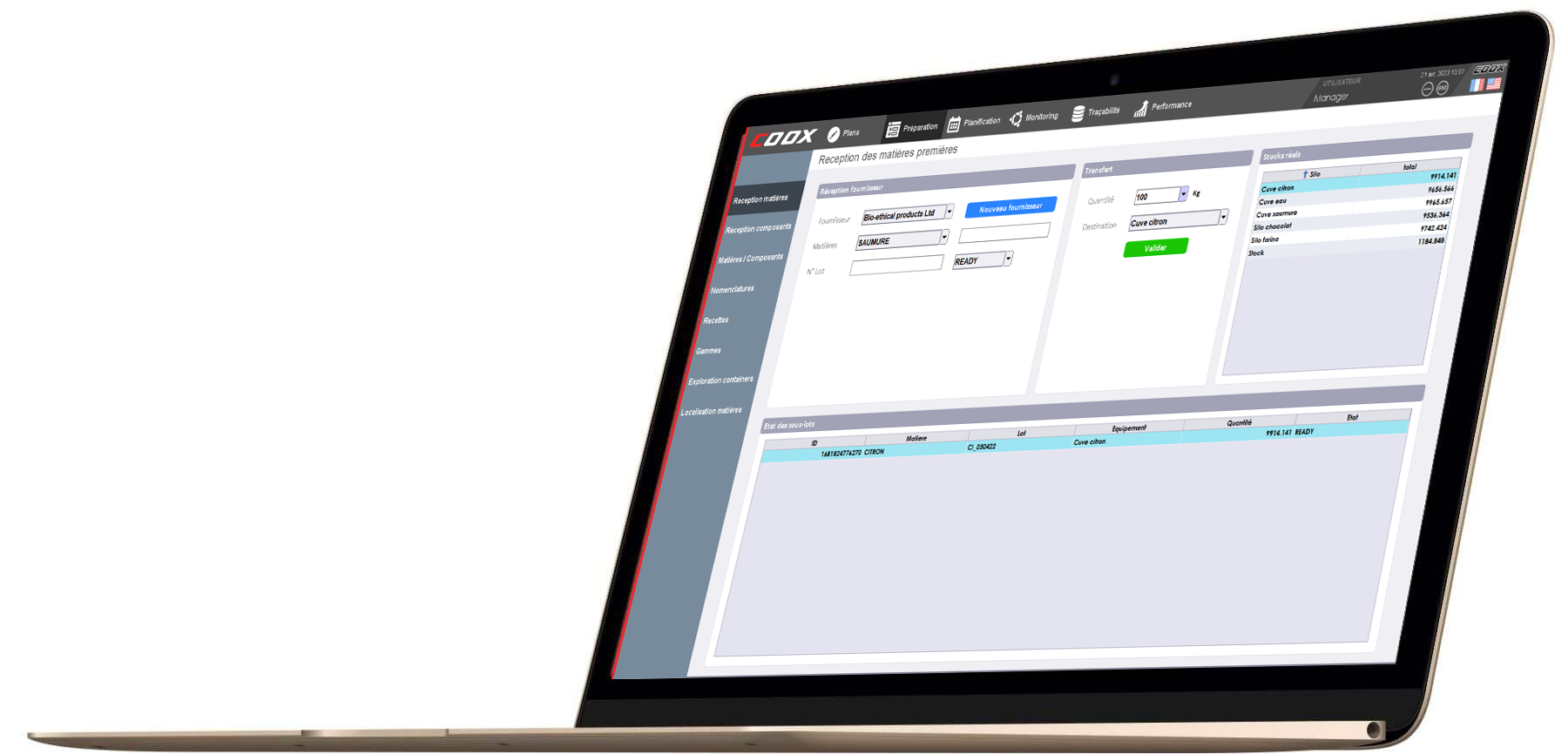

The COOX MES or MOM (Manufacturing Operations Management) software is the heart of the smart factory. It allows you to control and optimize all stages of production, from manufacturing orders from the ERP or your management system, to storage or shipping of products. Connected to your ERP, COOX (COllaborative Operation & eXecution) collects all your production data in real time and provides the manufacturer with overall production monitoring. This data is then analysed to allow you to

continuously improve the performance of your installations, to react and anticipate breakdowns and hazards in your production instead of suffering them. Thanks to its innovative modeling technology, the COOX MES software adapts to any type of industrial process and any installation configuration. The models (of equipment, operation, etc.) are reusable on one or more sites. They contribute to the speed of deployment and the robustness of applications.

Control your production in real time at the heart of your industrial site thanks to the MES COOX platform and MESbox modules. Advanced and proven solution, quick to set up, COOX allows you to optimize your industrial operations, improve your production and reduce your costs!

- Integrated and modular offer, scalable according to your needs

- Perfect adaptation to any manual or automated process by modeling

- Systematic traceability of any operation or material transfer

- Easy to set up and secure web architecture

- From individual machine to complete plant and multi-site deployment

The benefits of MES COOX software for manufacturers

- Data updated in real time (unlike ERP)

- Immediate vision of actual production compared to objectives

- Instant calculation of the actual cost price of products

- Reliability of figures transmitted in reporting

- Regulatory conformity

- Improvement of quality indicators

- Suitability for customer specifications

- Compliance with procedures

- Production in line with objectives

- Immediate identification of staff required to ensure planned production

- Precise vision of operator availability in the event of exceptional production

- Respect of order deadlines

- Precise information on the number and duration of equipment breakdowns

- Reductions in the most penalizing breakdowns

- Scheduling maintenance outages at the best time

- Immediate knowledge of the response team at a specific time

- Real-time view of the progress of the activity

- Precise indications of the tasks to be carried out

- Easy access to necessary documents

- Save time when filling out work sheets

- Guidance in delicate operations

- Real-time view of outstanding stock

- Immediate knowledge of the reasons in the event of a breakup

- Precise information on the quantity started on the last delivery ordered

- Exact indication of the order date to be placed for the next productions

- Total responsiveness in the event of supplier delay

Features delivered by the COOX MES software

Performance analysis - Indicators - OEE - KPI

Quality and industrial performance are part of the for continuous improvement of manufacturing processes (TPM approach : Toal Productive Management). Key Performance Indicators OEE calculation and monitoring Real-time graph display

Production quality monitoring

Quality, an essential component of production monitoring, is a transverse function that operates from the receipt of raw materials to the delivery of products. Multi-level Quality controls Quality rate and performance in real-time Continuous improvement

Products traceability - Genealogy

In order to guarantee the quality of their products and comply with increasingly demanding legislation, industries must have now an effective product traceability. Containers and transfers modeling Systematic traceability of material flows Detailed genealogy of batches and used equipments

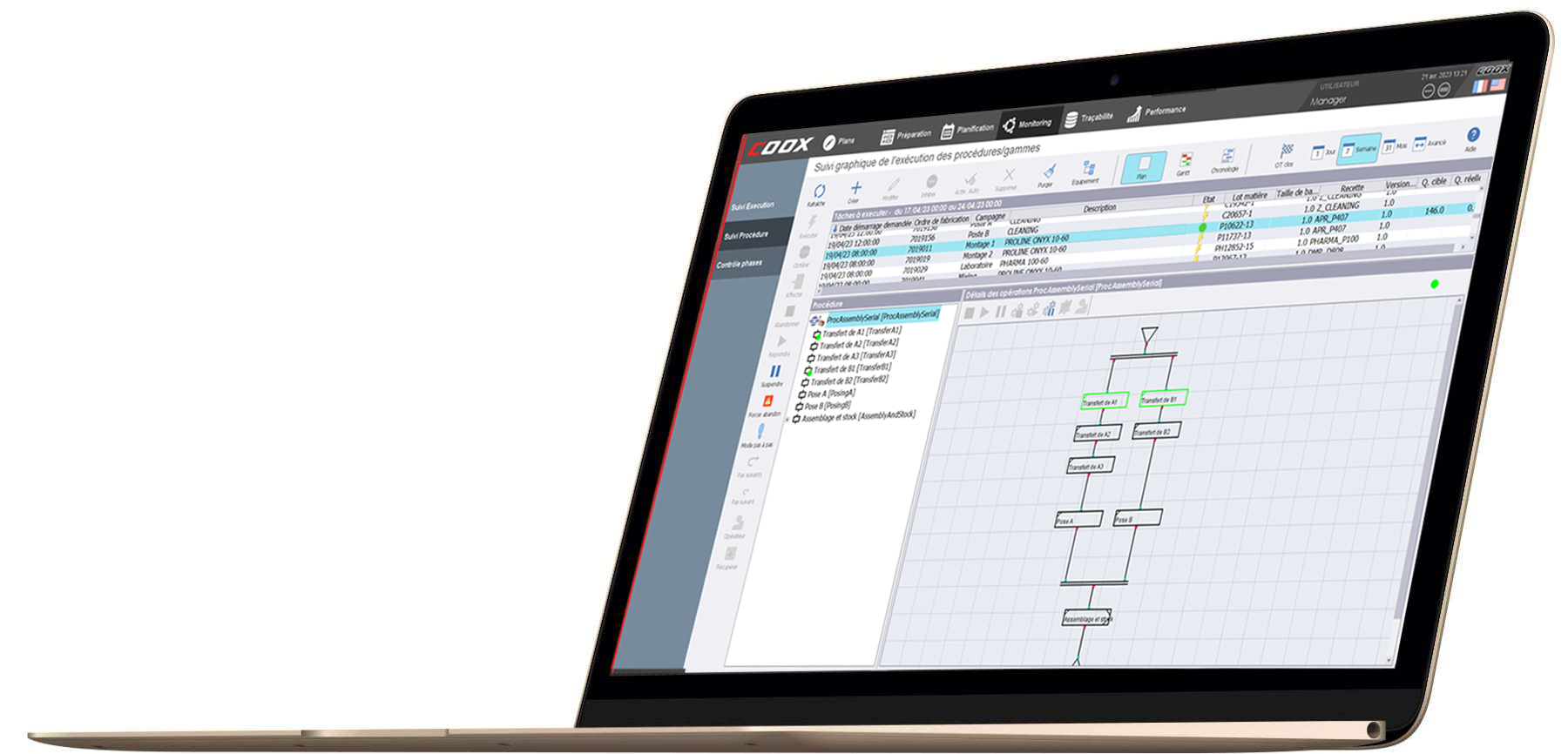

Operating procedures monitoring - Process traceability - Batch file

Key to productivity and quality, process control is now a challenge for all industries. Process control Systematic process traceability Electronic Batch File

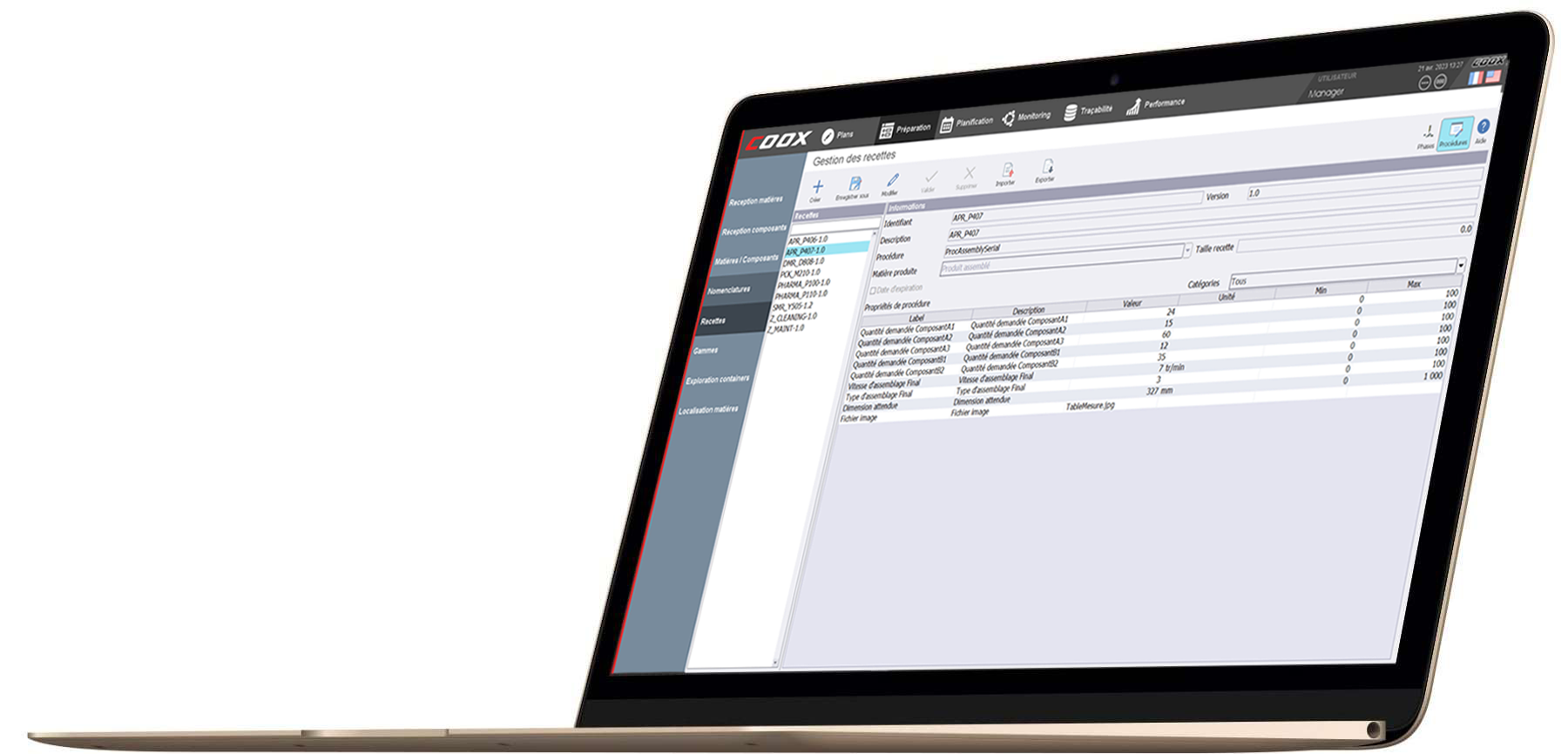

Recipes and bill of operations management - Formulas and BOMs

Essential for the control and execution of your production, product definitions can either be sent by your ERP but is often created or completed in the MES. Recipes definition Process modeling Recipes and multi-step procedures

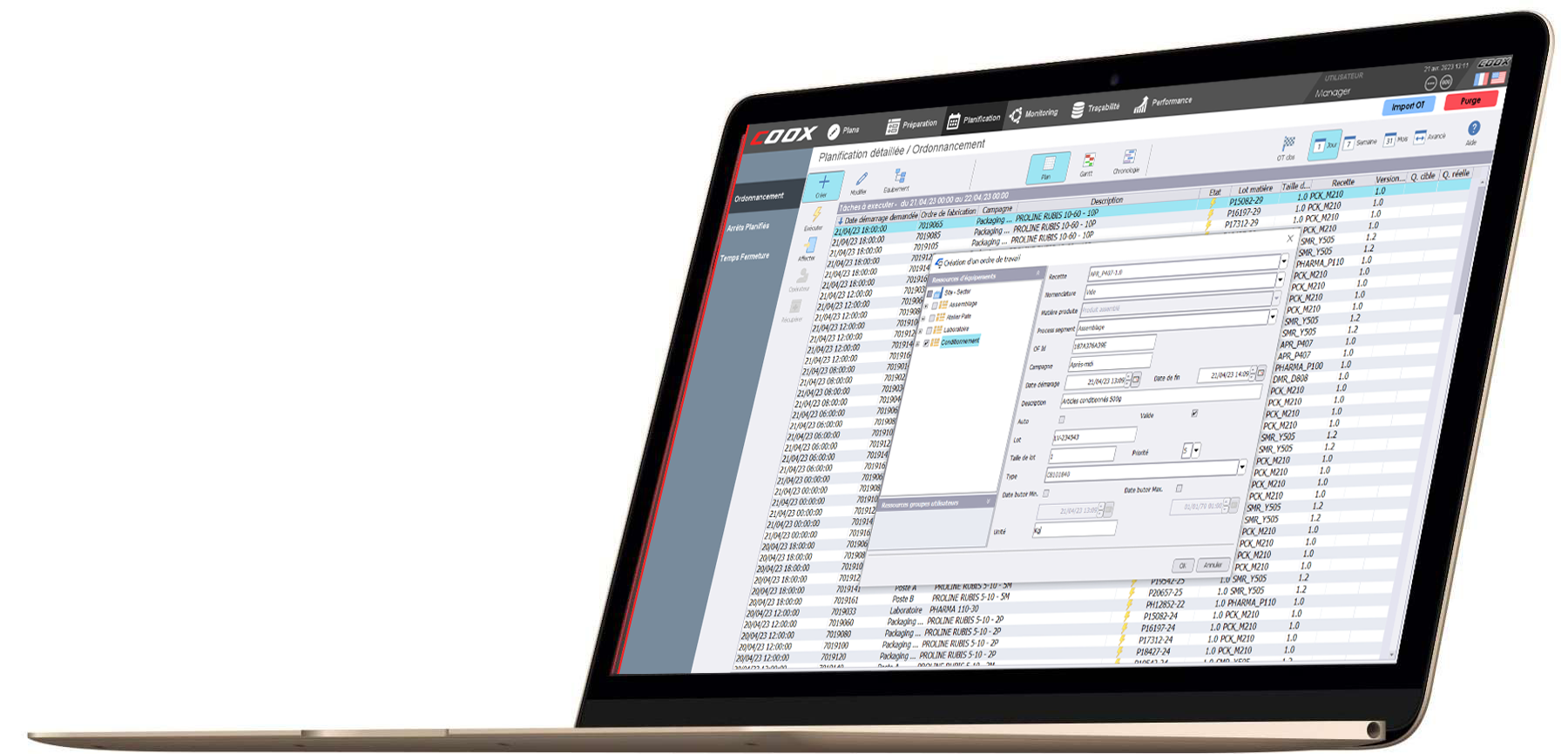

Production orders management

Production orders will allow to sequence the manufacture according to the orders to be delivered. Import from ERP Launching and monitoring production orders Automatic management of resource allocation

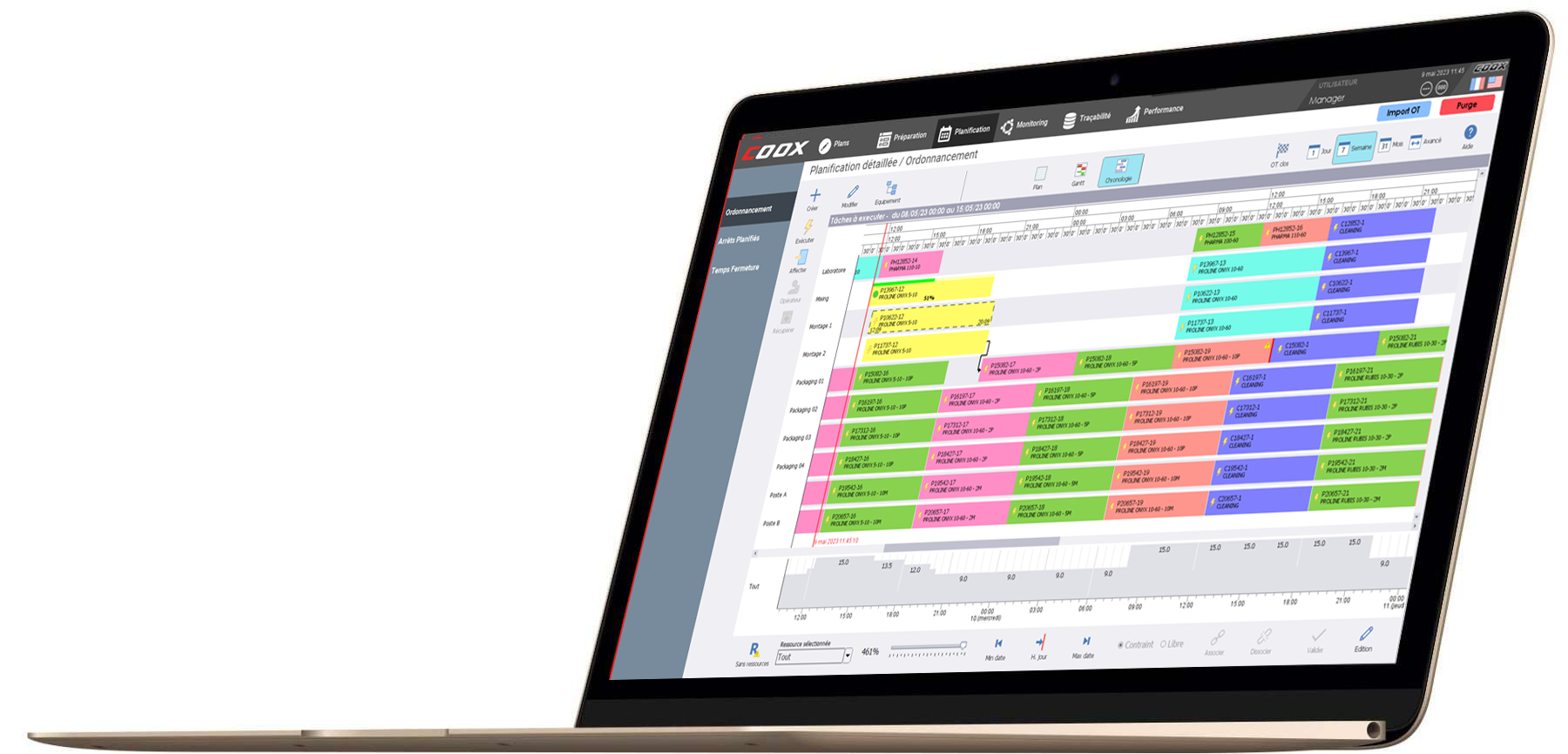

Planning - Scheduling - Detailed Planning

Transmitted by the ERP or the production management to the MES software, production orders can also be created directly. Planning production orders Control of their execution Real-time visualization of production phases

Material flow and inventory management

Perfect visibility on material flows, whether raw materials or products : an essential stake for production. Comprehensive tracking of batches Immediate identification of their location Optimal inventory management

Staff, manpower and teams management

Production monitoring or MES functions do not replace the management of the company's personnel, but provide the necessary information for the assignment of personnel on the workstations and their management as a production resource. Better resource management Control of the execution time of operations Optimization of the actual manufacturing cost of products