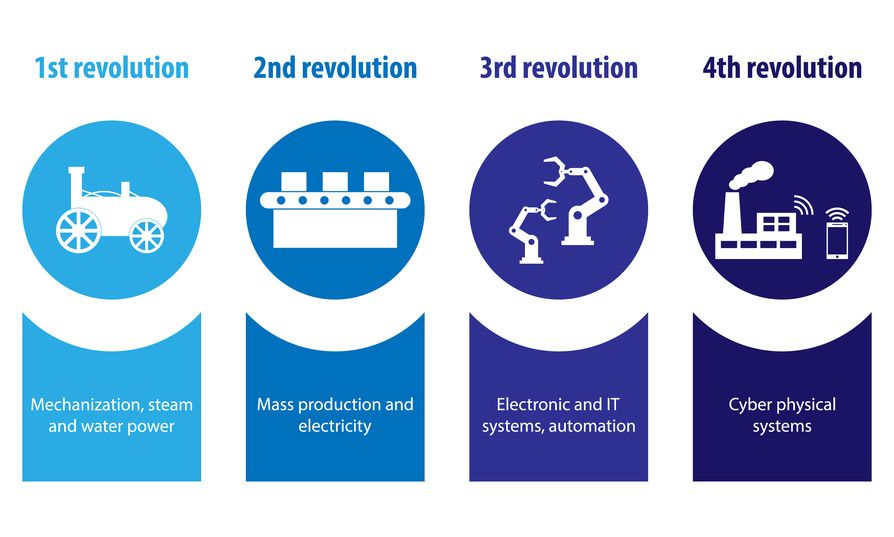

"Industry 4.0", "factory of the future", "factory 4.0" and "smart factory" are just some of the terms used to refer to this new factory model born of the 4th Industrial Revolution, the successor to the first three major evolutionary phases qualified as revolutions: mechanization, industrialization and automation.

This concept was introduced for the first time at the 2011 Hannover Messe trade fair. It describes a new way of organizing the means of production: setting up "smart" factories, where everything is done through interactions between products and machines, and between the machines themselves, all linked together over a network that is, in turn, connected to the outside world (instantaneous, continuous communication).We now find ourselves at the heart of an interconnected global system that is relevant to every company, big or small.

It's a technological revolution, encompassing numerous innovations and creating new market dynamics.

Inside factories, information technologies, communicative sensors, IIoT (Industrial Internet of Things), simulation software tools, information-processing software, management software, and the highest-performance machines are gradually making factories increasingly agile, efficient and competitive.

They're becoming more competitive, for example, through the use of an MES software for real-time material traceability and product genealogy, both within the factory and in the farthest reaches of the world. (In fact, industry 4.0 produces a constant stream of information that is so dense that it's often expected to be exchanged as quickly as possible - ideally in real-time - both internally and externally).

Not only are they better in terms of environmental security (reduced greenhouse gas emissions, waste reduction and recycling, etc.), but also in terms of cybersecurity, for example by using the network linked to the outside world to remotely control and manage production facilities, or else through virtual networks that control physical objects, enable production facilities to run self-diagnostics, and more.

The stakes are high - technologically speaking, of course, but also economically and culturally.

This new way of "digitizing" factories will make it possible to respond to the challenges of globalization and sourcing raw materials and energy resources, as well as offering better control over the security of industrial information systems.

The implementation of Industry 4.0 can be done very gradually. For example, the modernization of the plant's information system, the first step in digital transformation, generates moderate costs (it is not necessary to modify the production tool deeply) and is likely to bring about a quick return on investment (often less than a year) by reducing non-qualities, operations without added value and increasing the responsiveness of production. These gains can then help finance other stages of the industry's development. The modularity of COOX solution makes this approach even easier.