Quality and industrial performance are part of the for continuous improvement of manufacturing processes (TPM approach : Toal Productive Management).

Understanding, monitoring and improving the process are key challenges for Production Managers. Continuously improving the quality of your products and the performance of your industrial equipment requires relevant analytical tools and indicators. With the MESbox QPI pack, you have a powerful calculation and monitoring module for OEE, Overall return, MTBF, MTTR, Quality rate...and all associated indicators, as well as the ability to easily create your own production performance analysis (Key Performance Indicators).

For the manager

COOX (COllaborative Operation & eXecution) offers customizable ready-to-use dashboards: real-time vision of the selected standard performance indicators and their evolution over time over the chosen period. Adjustable thresholds for each device set the acceptability and alert levels for the indicators. In one click you get a detailed analysis of the causes of shutdowns and rejects.

For the operator

The causes of shutdowns and rejects which are not provided directly by the machines are automatically counted by ergonomic tactile interfaces. No loss of production time for text or time input, and more risk of error. The operator has access to the main information of the team in real time and increases their motivation to achieve production objectives.

Understanding, monitoring and improving the process are key challenges for Production Managers. Continuously improving the quality of your products and the performance of your industrial equipment requires relevant analytical tools and indicators. With the MESbox QPI pack, you have a powerful calculation and monitoring module for OEE, Overall return, MTBF, MTTR, Quality rate...and all associated indicators, as well as the ability to easily create your own production performance analysis (Key Performance Indicators).

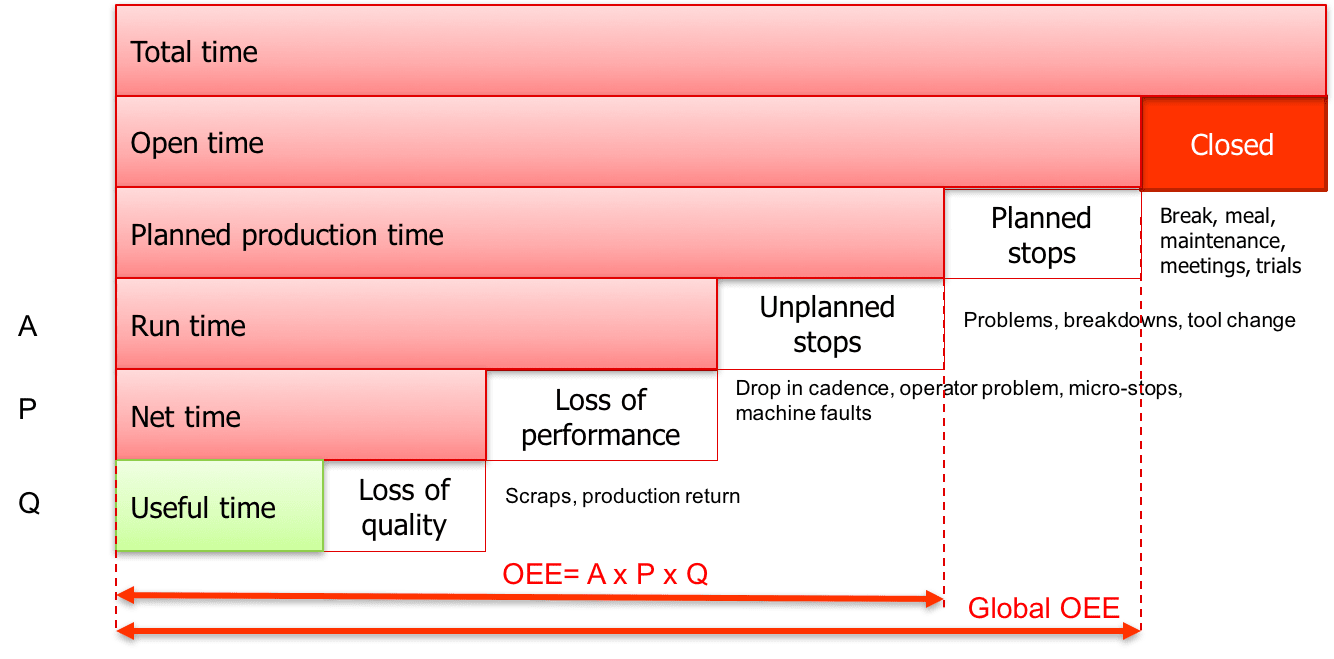

The E60-182 standard

The E60-182 standard sets the vocabulary and calculation method for the various production indicators which will allow the industries to determine the performance of a production tool. By calculing these various indicators in real time, the industrialist will be able to study more closely the elements that make up these calculations, adjust and vary them, and thus directly and immediately identify their impact on the overall result.

OEE monitoring

Time is precious and the industrialist must not lose it by making all sorts of calculations...From the information acquired automatically (from a PLC or fromp an input-output device) or manually, the MESbox QPI calculates directly and in real time all OEE data and their reference time and provides :

- Availability A, that identifies and seeks to reduce the plant's availability losses

- Performance rate P, that identifies and seeks to reduce performance losses such as drop rate or machine defect

- Quality rate Q, that identifies and seeks to reduce quality's losses (rejects, restatements))

The MESbox QPI also provides standard indicators as MTBF (Mean Time Between Failure) or MTTR (Mean Time To Repair). The calculations fo all these indicators are customizable.

In automatic mode, the OPC, TCP/MODBUS and Applicom/Woodhead/Molex communications are provided standard. The data collected (results of quality controls, product counts, materials consumptions,etc.) are recorded automatically in a standard database.

The module allows the extraction of dataaccording to different criteria : time, day, week, month, team, batches, production orders...

The indicators and states diffuser section disseminates real-time performance indicators on the intranet and instantly creates PDF and high level graphical reports.

Clear analysis reports by batches, time period or product available anytime, electronically or printed edited.

Real-time graph display

The MESbox QPI pack gives you direct access to the database template, and sets up customized filters. Graphs completely tailored to your needs (tables, histograms, and 2D or 3D sector diagrams, etc.), information such as quality, shutdown distribution, materials or consumables assessment, or operating time analyses, are distributed on the entire Intranet and accessible to the users concerned.

The company thus has a real centralization of the information, reliable, which everyone can share and which allows the different operators to react immediately and optimize each of their actions in real-time.

SPC (Statistic Process Control) and SQC (Statistic Quality Control)

SPC uses techniques such as incoming inspection, Pareto charts, and capability checks to determine the steps required to improve any industrial production process.

The purpose of online production control is to obtain stable production and to minimize the number of products non-compliant with specifications.

CORRESPONDING MODULES OF THE COOX® RANGE

The performance analysis and production indicators calculation functions are based on MESbox QPI module (Quality Performance & Indicators) of the COOX range. It allows you to natively obtain many indicators of production performance: OEE, Operation Availability, Quality rate, Overall return, MTBF, MTTR...and all associated indicators.

• Monitoring quality, quality rates, and discards

• Calculating standard OEE and related indicators, or custom performance indicators

• Calculating standard MTBF (mean time between failures), MTTR (mean time to repair), or custom maintenance indicators

• Monitoring materials consumption and assessments

• Automatic acquisition or manual entry of information

• Support for SQL Server™, Oracle™ and MySQL™ databases

• Output formats: PDF™, Excel™ and texte

• Generation and distribution of dynamic graphs formulated with Excel™

• Predefined models and creation of report models

• Customizable report options established in operations (filters, selections, etc.)